| DESCRIPTION |

SPECIFICATION |

Q’TY(SET) |

| INDUCTION FURNACE |

3.5 TON (1 SOURCE 1 BODY) |

2 Unit |

| INDUCTION FURNACE |

2.5 TON (1 SOURCE 1 BODY) |

1 Unit |

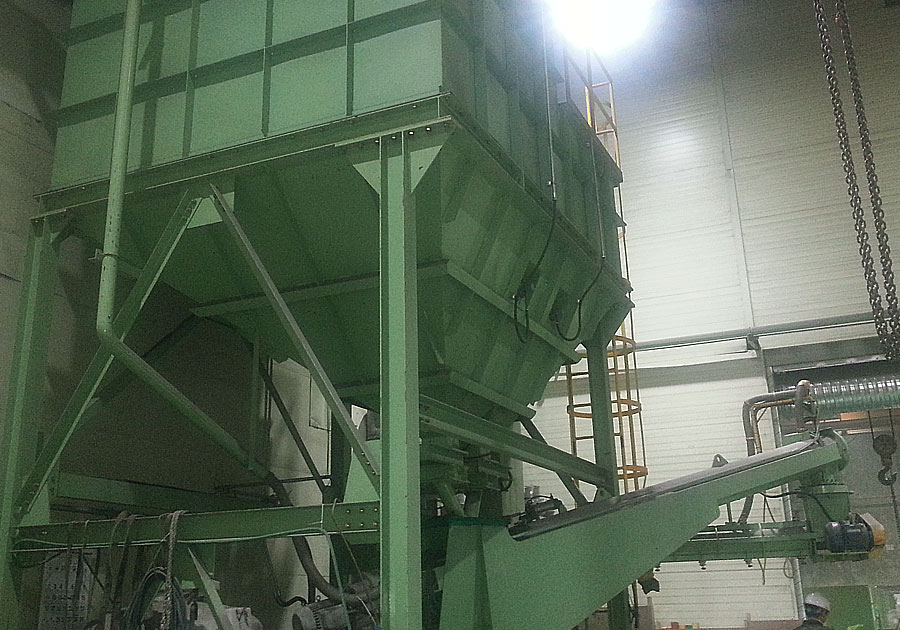

| MOLDING PROCESS |

ALPHA-SET PROCESS (CERAMIC SAND) |

2 Unit |

| CONTINUOUS MIXER |

10 TON / HR, 5TON/HR |

1 Set |

| SHOT BLAST M/C |

5 TON, 15 TON |

2 |

| CRANES |

2.8 TON ~ 30 TON |

11 |

| AIR COMPRESSOR |

50HP,100HP |

2 |

| STOPPER LADLE |

10 Ton |

1 |

| ARC WELD M/C |

30KW |

10 |

| TIG WELD M/C |

500A |

5 |

| GAUGING M/C |

2400A |

1 |

| GAUGING M/C |

1300A |

3 |

| HIGH FREQUENCY GRINDER |

4”, 7” |

20 |

| HEAT TREATMENT |

PIT TYPE ELECTRIC FURNACE |

Φ2,000x 2,000(H) |

1 |

| BOX TYPE ELECTRIC FURNACE |

3,200 x 3,200 x 2,200(H) |

1 |

| WATER TANK |

5,000x12,000x3,500(H) |

1 |

| MACHINING |

NC TURNING M/C(SHIBAURA) |

Table size : Φ3,000x3000(H) (max. Φ3,500x3,000(H)) |

1 |

| TURNING M/C(OM-Ltd.) |

Table size : Φ1,600x2,000(H) |

2 |

| NC BORING M/C(TOSHIBA) |

Φ110 X 1200L |

1 |

| RADIAL M/C(BONG SHIN) |

2,000Lx 2,000H |

1 |